Layin Samar da Stamping mai saurin zafi don Karfe mai ƙarfi mai ƙarfi (Aluminum)

Mabuɗin fasali

An tsara Layin samarwa don inganta tsarin masana'antu na sassa na motoci ta hanyar aikace-aikacen fasaha mai zafi. Wannan tsari, wanda aka fi sani da tambarin zafi a Asiya da latsa hardening a Turai, ya haɗa da dumama kayan da ba komai ba zuwa wani takamaiman zafin jiki sannan danna shi a cikin gyare-gyare masu dacewa ta amfani da fasahar latsa na'ura mai aiki da karfin ruwa yayin da ake ci gaba da matsa lamba don cimma siffar da ake so da kuma jujjuya canjin lokaci na kayan ƙarfe. Za'a iya rarraba dabarar hatimi mai zafi zuwa hanyoyin yin hatimi kai tsaye da kaikaice.

Amfani

Ɗaya daga cikin mahimman fa'idodin abubuwan haɗin gine-gine masu zafi mai zafi shine kyakkyawan tsari na su, wanda ke ba da damar samar da hadaddun geometries tare da keɓaɓɓen ƙarfin ƙarfi. Ƙarfin ɓangarorin zafi mai zafi yana ba da damar yin amfani da zanen ƙarfe na bakin ciki, rage nauyin abubuwan haɗin gwiwa yayin da yake kiyaye tsarin tsari da aikin haɗari. Sauran fa'idodin sun haɗa da:

Rage Ayyukan haɗin gwiwa:Fasahar hatimi mai zafi tana rage buƙatar walda ko haɗa ayyukan haɗin gwiwa, yana haifar da ingantacciyar inganci da ingantaccen ingancin samfur.

Rage Ragewar Springback da Shafin War:Tsarin hatimi mai zafi yana rage nakasar da ba'a so, kamar ɓangaren bazara da wargin, yana tabbatar da daidaiton girman girman da rage buƙatar ƙarin sake yin aiki.

Kadan Lalacewar Sashe:Sassan da aka buga masu zafi suna nuna ƙarancin lahani, kamar tsagewa da rarrabuwa, idan aka kwatanta da hanyoyin ƙirƙirar sanyi, yana haifar da ingantacciyar ingancin samfur da rage sharar gida.

Ƙananan Latsawa:Hot stamping yana rage yawan latsawa da ake buƙata idan aka kwatanta da dabarun ƙirƙira sanyi, yana haifar da tanadin farashi da haɓaka haɓakar samarwa.

Keɓance Abubuwan Kayayyaki:Fasaha mai zafi mai zafi yana ba da damar gyare-gyaren kayan kayan aiki bisa ƙayyadaddun wurare na ɓangaren, inganta aiki da aiki.

Ingantattun Ɗaukaka Ƙirƙirar Ƙirƙirar Ƙira:Hot stamping yana ba da damar haɓaka microstructure na kayan aiki, yana haifar da ingantattun kayan aikin injiniya da ƙara ƙarfin samfur.

Matakan Samar da Sauƙaƙe:Zafafan hatimi yana kawar da ko rage matsakaicin matakan masana'antu, yana haifar da sauƙaƙe tsarin samarwa, haɓaka yawan aiki, da gajeriyar lokutan jagora.

Aikace-aikacen samfur

Ƙarfe Mai Ƙarfi (Aluminum) High-Speed Hot Stamping Production Line ya sami aikace-aikace mai yawa a cikin masana'antun fararen sassan jiki na mota. Wannan ya haɗa da tarukan ginshiƙai, ƙorafi, katakon ƙofa, da tarukan dogo na rufin da ake amfani da su a motocin fasinja. Bugu da ƙari, ana ƙara yin bincike game da amfani da na'urori na zamani waɗanda aka kunna ta tambari mai zafi a cikin masana'antu kamar sararin samaniya, tsaro, da kasuwanni masu tasowa. Wadannan allunan suna ba da fa'idodi na ƙarfi mafi girma da rage nauyi waɗanda ke da wahalar cimma ta hanyar wasu hanyoyin ƙirƙirar.

A ƙarshe, Ƙarfe Mai Ƙarfi (Aluminum) High-Speed Hot Stamping Production Line yana tabbatar da daidai da ingantaccen samar da sassan jikin mota masu rikitarwa. Tare da ingantaccen tsari, rage ayyukan haɗin gwiwa, raguwar lahani, da haɓaka kayan abu, wannan layin samarwa yana ba da fa'idodi masu yawa. Aikace-aikacen sa sun haɓaka zuwa kera sassan jikin fararen fata don motocin fasinja kuma suna ba da fa'idodi masu yuwuwa a cikin sararin samaniya, tsaro, da kasuwanni masu tasowa. Zuba jari a cikin Babban Karfe Mai ƙarfi (Aluminum) Layin Samar da Haɓaka Mai Sauƙi don cimma kyakkyawan aiki, yawan aiki, da fa'idodin ƙira mai nauyi a cikin masana'antu na kera motoci da ƙawance.

Menene zafi stamping?

Hot stamping, wanda kuma aka sani da latsa hardening a Turai da zafi latsa forming a Asiya, wata hanya ce ta abu forming inda wani blank ne mai tsanani zuwa wani zafin jiki sa'an nan a buga da quenched karkashin matsa lamba a daidai mutu don cimma siffar da ake so da kuma haifar da wani lokaci canji a cikin karfe kayan. Fasaha stamping mai zafi ya haɗa da dumama zanen ƙarfe na boron (tare da ƙarfin farko na 500-700 MPa) zuwa jihar austenitizing, da sauri canja wurin su zuwa ga mutu don yin hatimi mai sauri, da kashe ɓangaren da ke cikin mutu a ƙimar sanyaya sama da 27 ° C / s, sannan lokacin riƙewa ƙarƙashin matsin lamba, don samun babban ƙarfin ƙarfe mai ƙarfi tare da kayan aikin ƙarfe mai ƙarfi.

Amfanin zafi mai zafi

Ingantacciyar ƙarfin juriya na ƙarshe da ikon samar da hadaddun geometries.

Rage nauyin abun da ke ciki ta yin amfani da ƙaramin ƙaramin takarda yayin da yake kiyaye amincin tsari da aikin faɗuwa.

Rage buƙatun haɗa ayyuka kamar walda ko ɗaki.

Rage girman ɓangaren bazara baya da warping.

Ƙananan lahani kamar tsagewa da tsaga.

Ƙananan buƙatun ton latsa idan aka kwatanta da sanyin kafa.

Ikon keɓance kaddarorin kayan aiki bisa takamaiman yanki na yanki.

Ingantattun microstructures don ingantaccen aiki.

Tsarin masana'anta mai sauƙi tare da ƙananan matakan aiki don samun samfurin da aka gama.

Waɗannan fa'idodin suna ba da gudummawa ga haɓaka gabaɗaya, inganci, da aiki na abubuwan haɗin ginin hatimi mai zafi.

Ƙarin cikakkun bayanai game da hatimi mai zafi

1.Hot Stamping vs Cold Stamping

Zafafan hatimi wani tsari ne da ake yin shi bayan an riga an gama ɗumamar takardar ƙarfe, yayin da tambarin sanyi yana nufin yin hatimi kai tsaye na takardar ba tare da preheating ba.

Cold stamping yana da fa'idodi masu fa'ida akan tambarin zafi. Duk da haka, yana kuma nuna wasu rashin amfani. Saboda matsanancin damuwa da tsarin sanyi na sanyi ya haifar idan aka kwatanta da zafi mai zafi, samfurori masu sanyi sun fi sauƙi ga raguwa da rarrabuwa. Sabili da haka, ana buƙatar ainihin kayan aikin hatimi don yin hatimin sanyi.

Tambarin zafi ya ƙunshi dumama takardar karfe zuwa yanayin zafi mai zafi kafin yin tambari da kuma kashewa a lokaci guda. Wannan yana haifar da cikakken canji na ƙananan ƙananan ƙarfe zuwa martensite, wanda ya haifar da babban ƙarfi daga 1500 zuwa 2000 MPa. Sakamakon haka, samfuran da aka hatimi masu zafi suna nuna ƙarfi mafi girma idan aka kwatanta da takwarorinsu masu sanyi.

2.Hot Stamping Tsarin Guda

Zafafan hatimi, wanda kuma aka sani da "ƙarƙashin latsawa," ya haɗa da dumama takarda mai ƙarfi tare da ƙarfin farko na 500-600 MPa zuwa yanayin zafi tsakanin 880 zuwa 950 ° C. Za a iya buga takarda mai zafi da sauri kuma a kashe shi a cikin mutu, ana samun yanayin sanyi na 20-300 ° C/s. Canji na austenite zuwa martensite a lokacin quenching yana haɓaka ƙarfin ɓangaren, yana ba da damar samar da sassan da aka hatimi tare da ƙarfin har zuwa 1500 MPa. Za a iya rarraba fasahohin hatimi na zafi zuwa kashi biyu: tambarin zafi kai tsaye da tambarin zafi kai tsaye:

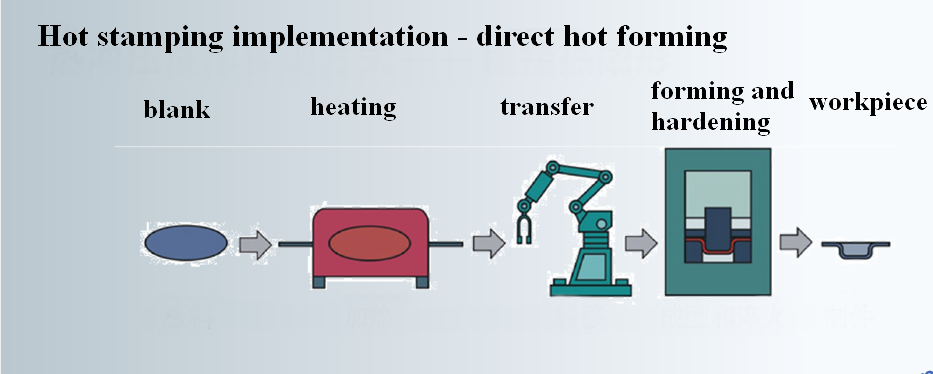

A cikin hatimi mai zafi kai tsaye, babu abin da aka rigaya da aka rigaya ana ciyar da shi kai tsaye a cikin rufaffiyar mutu don yin tambari da kashewa. Hanyoyin da suka biyo baya sun haɗa da sanyaya, gyare-gyaren gefen da hushi (ko yankan Laser), da tsaftacewa.

Fiture1: yanayin sarrafa hatimi mai zafi-- kai tsaye zafi tambari

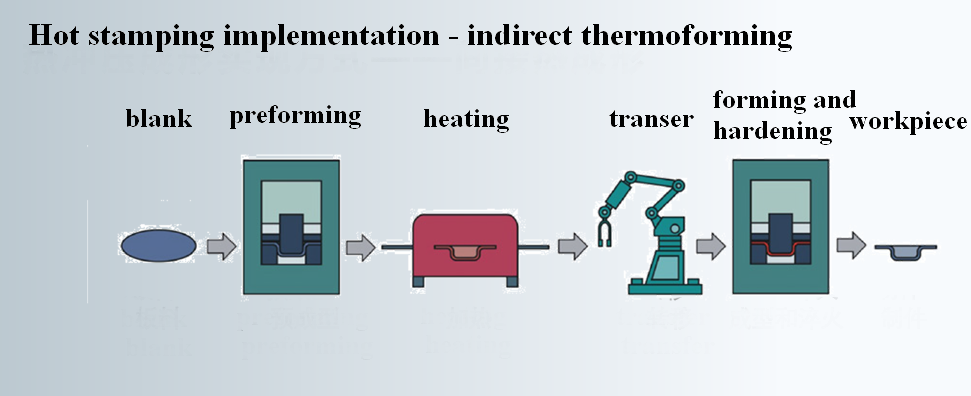

A cikin tsari mai zafi na kaikaice, ana yin matakin da aka fara siffata sanyi kafin shigar da matakan dumama, tambarin zafi, datsa gefen, naushin rami, da tsaftace ƙasa.

Babban bambanci tsakanin kai tsaye zafi stamping da kai tsaye zafi stamping matakai ya ta'allaka ne a cikin hada da sanyi kafa pre-siffata mataki kafin dumama a kaikaice hanya. A cikin tambarin zafi kai tsaye, ana ciyar da ƙarfen takarda kai tsaye a cikin tanderun dumama, yayin da a kaikaice tambarin zafi, ana aika ɓangaren da aka riga aka yi da sanyi a cikin tanderun dumama.

Tsarin tafiyar da hatimi mai zafi kaikaice ya ƙunshi matakai masu zuwa:

Cold forming pre-siffata-- Dumama-Zafafan hatimi-- Gyaran baki da hushi rami-Tsaftar saman.

Fiture2: yanayin sarrafa hatimi mai zafi-- kaikaice zafi tambari

3.The main kayan aiki ga zafi stamping hada da dumama makera, zafi kafa latsa, da zafi stamping molds.

Tushen Dumama:

Gidan wutar lantarki yana sanye da dumama da ikon sarrafa zafin jiki. Yana da ikon dumama manyan faranti masu ƙarfi zuwa zazzabi na recrystallization a cikin ƙayyadadden lokaci, cimma yanayin austenitic. Yana buƙatar samun damar daidaitawa zuwa manyan buƙatun samar da ci gaba mai sarrafa kansa. Kamar yadda robobi mai zafi za a iya sarrafa shi ta mutum-mutumi ko makamai, tanderun na buƙatar lodawa ta atomatik da saukewa tare da babban matsayi. Bugu da ƙari, lokacin dumama faranti na ƙarfe mara rufi, ya kamata ya ba da kariya ta iskar gas don hana iskar oxygen da lalatawar billet.

Zafafan Ƙarfafa Ƙarfafawa:

Latsa shine jigon fasahar tambarin zafi. Yana buƙatar samun damar yin hatimi da sauri da riƙewa, da kuma sanye take da tsarin sanyaya mai sauri. Fahimtar fasaha na matsi mai zafi mai zafi ya zarce na na'urar buga tambarin sanyi na al'ada. A halin yanzu, wasu kamfanoni daga kasashen waje ne kawai suka kware wajen kere-kere da kere-kere na irin wadannan na’urori, kuma duk sun dogara ne kan shigo da su daga kasashen waje, wanda hakan ya sa suke tsada.

Zafafan Stamping Molds:

Zafafan gyare-gyaren stamping suna yin matakai biyu na kafawa da kuma quenching. A cikin matakin kafawa, da zarar an ciyar da billet a cikin rami mai ƙura, ƙurawar ta cika aikin tambarin da sauri don tabbatar da ƙarshen samuwar sashe kafin kayan ya sami canjin yanayin martensitic. Sa'an nan, ya shiga cikin quenching da sanyaya mataki, inda zafi daga workpiece a cikin mold aka ci gaba da canjawa wuri zuwa mold. Bututun sanyaya da aka shirya a cikin ƙirar nan take cire zafi ta cikin injin sanyaya mai gudana. Canjin martensitic-austenitic yana farawa lokacin da zafin aikin aikin ya faɗi zuwa 425 ° C. Canji tsakanin martensite da austenite yana ƙare lokacin da zafin jiki ya kai 280 ° C, kuma ana ɗaukar aikin a 200 ° C. Matsayin riƙon ƙirar shine don hana haɓakar zafin jiki mara daidaituwa da raguwa yayin aikin kashewa, wanda zai iya haifar da manyan canje-canje a cikin sigar da girman ɓangaren, wanda zai haifar da guntuwa. Bugu da ƙari, yana haɓaka ƙimar canjin thermal tsakanin kayan aiki da ƙirar, yana haɓaka saurin kashewa da sanyaya.

A taƙaice, babban kayan aiki na zafi stamping hada da dumama tanderun ga cimma da ake so zafin jiki, zafi forming latsa don azumi stamping da kuma rike tare da m sanyaya tsarin, da zafi stamping molds cewa yi duka kafa da quenching matakai don tabbatar da dace part samuwar da ingantaccen sanyaya.

Gudun kwantar da hankali ba wai kawai yana rinjayar lokacin samarwa ba, amma kuma yana rinjayar tasirin juyawa tsakanin austenite da martensite. Adadin sanyaya yana ƙayyade irin nau'in tsarin crystalline da za a kafa kuma yana da alaƙa da tasirin taurin ƙarshe na aikin aikin. Mahimmancin zafin jiki mai sanyaya ƙarfe na boron karfe yana da kusan 30 ℃ / s, kuma kawai lokacin da adadin sanyaya ya wuce yanayin sanyi mai mahimmanci za a iya haɓaka samuwar tsarin martensitic zuwa mafi girma. Lokacin da adadin sanyaya ya yi ƙasa da ƙimar sanyaya mai mahimmanci, tsarin da ba na martensitic kamar bainite zai bayyana a cikin tsarin crystallization workpiece. Koyaya, mafi girman ƙimar sanyaya, mafi kyau, mafi girman ƙimar sanyaya zai haifar da fashewar sassan da aka kafa, kuma ana buƙatar ƙimar ƙimar sanyi mai dacewa bisa ga tsarin kayan aiki da yanayin aiwatar da sassan.

Tun da zane na sanyaya bututu yana da alaka kai tsaye da girman da sanyaya gudun, da sanyaya bututu gaba daya tsara daga hangen zaman gaba da zafi canja wurin yadda ya dace, don haka shugabanci na tsara sanyaya bututu ne mafi hadaddun, kuma yana da wuya a samu ta inji hakowa bayan kammala mold simintin gyaran kafa. Don gujewa ƙuntatawa ta hanyar sarrafa injina, hanyar tanadin tashoshi na ruwa kafin simintin gyare-gyare gabaɗaya ana zaɓin zaɓi.

Domin yana aiki na dogon lokaci a 200 ℃ zuwa 880 ~ 950 ℃ a karkashin sanyi mai tsanani da kuma zafi alternating yanayi, da zafi stamping mutu abu dole ne mai kyau tsarin rigidity da thermal watsin, kuma zai iya tsayayya da karfi thermal gogayya generated da billet a high zafin jiki da kuma abrasive lalacewa sakamako na dropped oxide Layer. Bugu da kari, da mold abu ya kamata kuma da kyau lalata juriya ga coolant don tabbatar da santsi kwarara na sanyaya bututu.

Gyarawa da hudawa

Saboda ƙarfin sassan bayan zafi mai zafi ya kai kimanin 1500MPa, idan an yi amfani da yankan latsa da nau'i, buƙatun tonnage na kayan aiki sun fi girma, kuma raguwar lalacewa yana da tsanani. Sabili da haka, ana amfani da sassan yankan Laser sau da yawa don yanke gefuna da ramuka.

4.Common maki na zafi stamping karfe

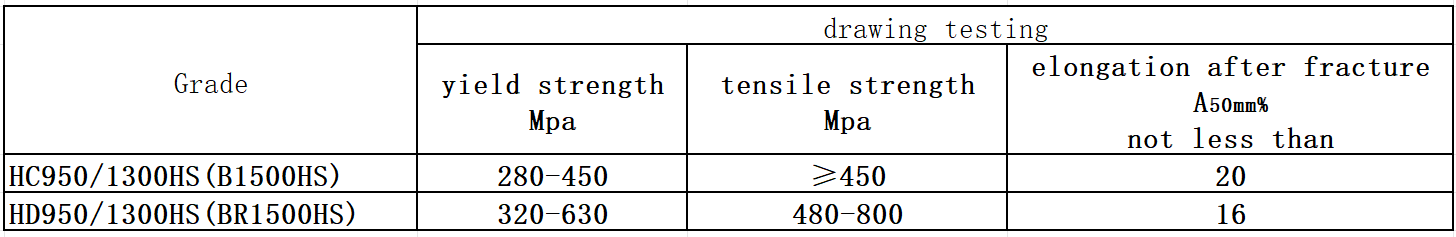

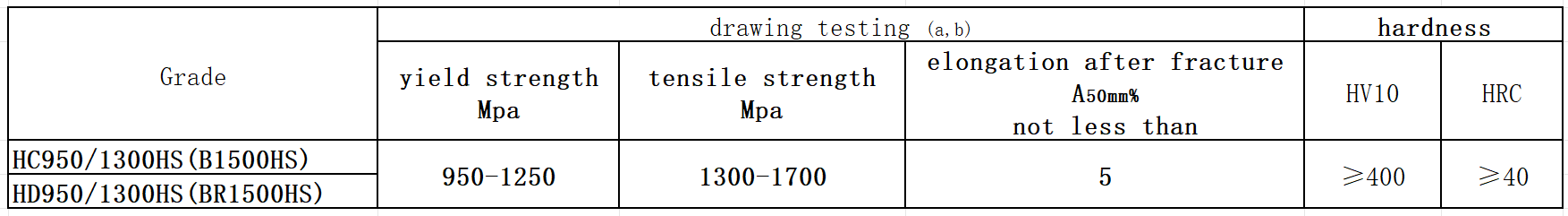

Aiki kafin yin hatimi

Performance bayan stamping

A halin yanzu, ƙimar gama gari na ƙarfe mai zafi shine B1500HS. Ƙarfin jujjuyawar kafin yin hatimi shine gabaɗaya tsakanin 480-800MPa, kuma bayan hatimi, ƙarfin tensile zai iya kaiwa 1300-1700MPa. Wato, ƙarfin ƙarfin 480-800MPa karfe farantin karfe, ta hanyar zafi stamping forming, iya samun tensile ƙarfi na game da 1300-1700MPa sassa.

5.Amfani da zafi stamping karfe

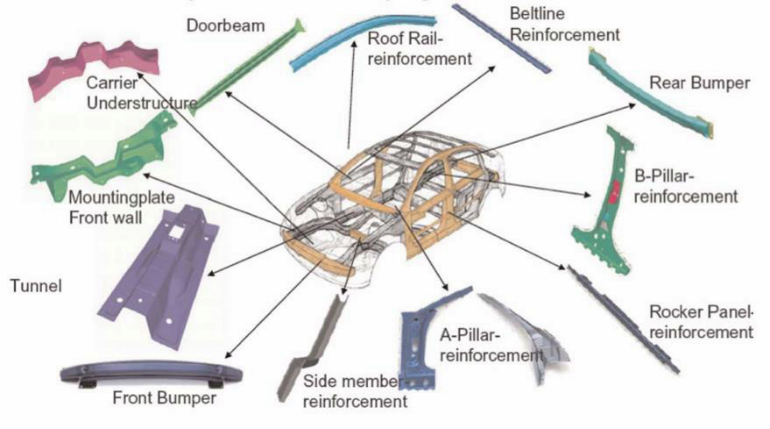

Aiwatar da sassa masu zafi na iya haɓaka amincin haɗarin mota da kuma gane nauyin jikin mota cikin farar fata. A halin yanzu, an yi amfani da fasahar tambarin zafi a sassan jikin fararen motocin fasinja, irin su mota, A ginshiƙi, B ginshiƙi, bumper, katakon ƙofa da rufin rufin da sauran sassa.Dubi hoto na 3 da ke ƙasa misali sassan da suka dace da ɗaukar nauyi.

adadi 3: Farin kayan jikin da suka dace da tambarin zafi

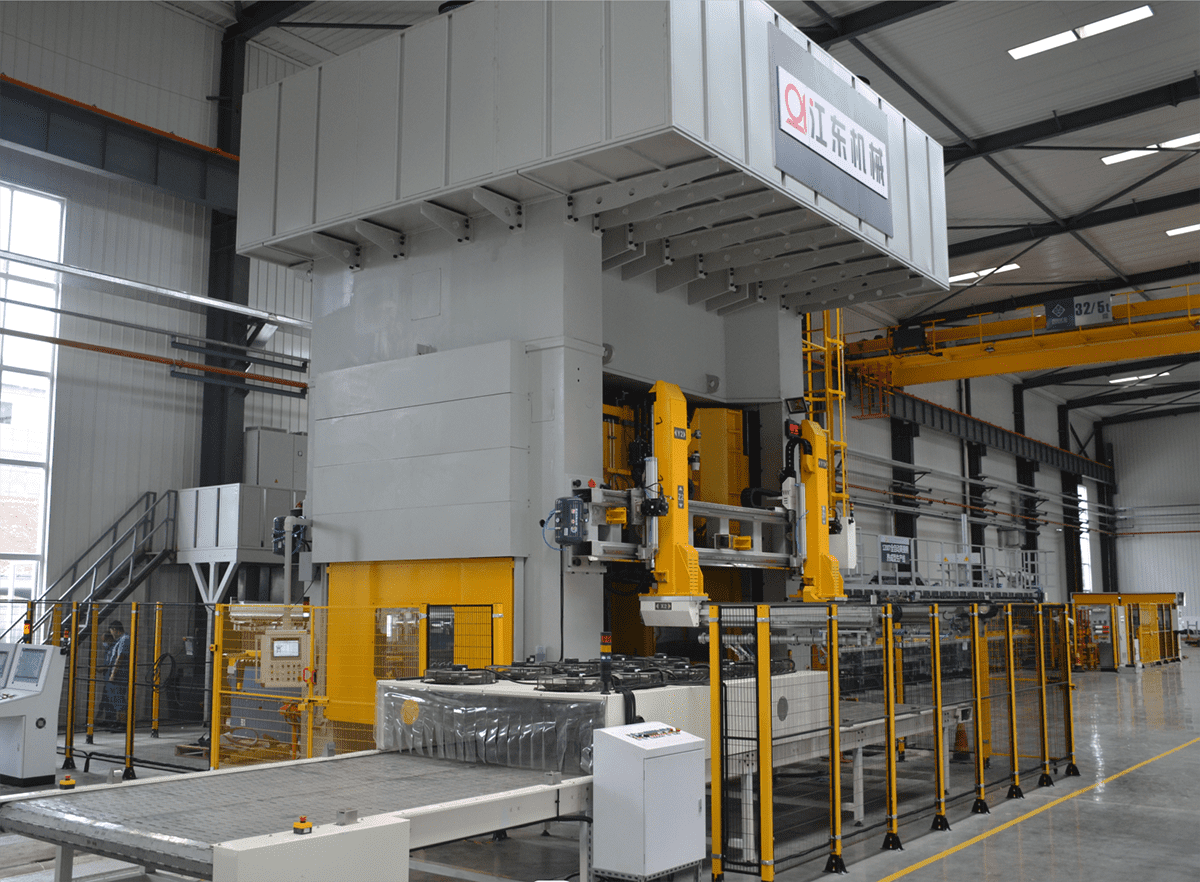

Hoto 4: Injin Jiangdong 1200 Ton Hot Stamping Layin Latsa Kashe

A halin yanzu, JIANGDONG injin zafi stamping na'ura mai aiki da karfin ruwa latsa samar line mafita sun kasance balagagge da kuma barga, a kasar Sin zafi stamping kafa filin nasa ne da manyan matakin, kuma a matsayin kasar Sin Machine Tool Association ƙirƙira inji reshe mataimakin shugaban naúrar, kazalika da memba raka'a na kasar Sin ƙirƙira inji Standardization kwamitin, mun kuma gudanar da bincike da kuma aikace-aikace na aluminium babban aiki na kasa da kasa hatimi a cikin manyan matakin, da kuma na kasa da kasa tari. inganta bunkasuwar masana'antar tambari mai zafi a kasar Sin da ma duniya baki daya.